How to Avoid Budget Overruns with Smarter Material Planning

There’s no faster way to derail a construction project than a busted budget.

When you’re managing a build—whether it’s a 200-unit development or a single-family home—your margins are already thin. Add in fluctuating material costs, tight timelines, and a few unexpected curveballs, and suddenly you’re staring down cost overruns that can put the entire project in jeopardy.

At ProPonents, we’ve seen this scenario play out far too often. A project launches with a clear financial plan, but a series of small missteps in material planning snowballs into delays, overspending, and stress that no contractor, superintendent, or developer wants to deal with.

But here’s the good news: most of those budget overruns? They’re preventable. And avoiding them doesn’t require magic. It just requires smarter material planning—and a supplier who’s willing to act like a partner, not just a middleman.

Let’s walk through how poor planning leads to financial setbacks—and how early, thoughtful procurement strategy can help you protect your budget, your timeline, and your peace of mind.

The Real Costs of Waiting Too Long

Material decisions are often made too late. The assumption is: "We’ll figure it out when we get there." But by the time you’re there—framing is underway, trades are on-site, and the clock is ticking—you don’t have the flexibility you had in pre-construction. Now, you’re reacting. That reaction often comes at a premium.

You might be forced to pay expedited freight because a critical material didn’t arrive on time. Or maybe the spec’d product is suddenly backordered, and you’re scrambling to find a substitute that’s both available and approved. Sometimes, you’ll reorder materials due to overages, waste, or miscounts—doubling your spend on a single line item without realizing it.

And then there’s the most frustrating cost of all: lost time. Every day your crew waits on-site without the right materials is money down the drain. Labor waste, schedule slips, and idle trades create a ripple effect that’s hard to recover from—especially if you’re working under tight contract deadlines.

All of these issues come back to one thing: planning too late and relying on reactive purchasing.

Proactive Planning Pays Off

We believe that material procurement should start long before boots hit the ground. In fact, the earlier you involve your supplier in the conversation, the more opportunities you have to control costs.

At ProPonents, we don’t wait for the order to come through to start thinking. We want to be involved in the budgeting and planning phase—when there’s still time to identify risks, explore options, and map out a strategy that supports your bottom line.

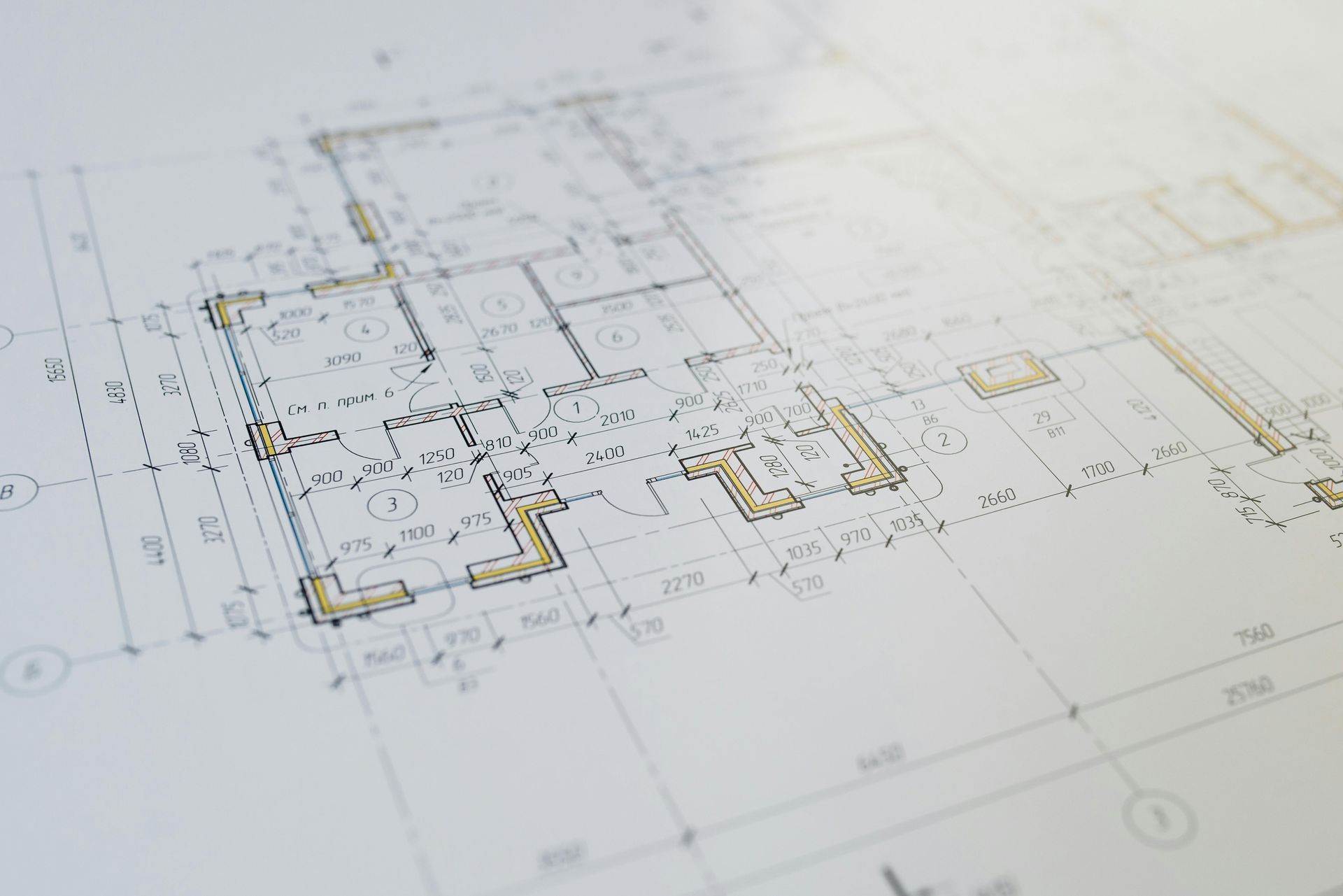

When we work with a client early in the process, we begin by reviewing your plans and understanding the build sequence. We talk through your ideal delivery windows, your staging conditions, your subcontractor schedule, and your priorities—whether that’s lowest cost, shortest lead time, or longest lifespan. Then, we build a materials plan around your reality, not just a spreadsheet.

That plan includes sourcing materials that align with your budget, locking in prices where possible to protect you from inflation, and scheduling deliveries to match your build phases. It also means thinking ahead: what are your backup options if your primary materials face a delay? Where are the pressure points in your timeline, and how can we help you avoid them?

This isn’t about filling a truck. It’s about supporting a project from the ground up with intentional, informed procurement strategy.

A Case Study in Savings

Not long ago, we worked with a developer who came to us after their first phase had gone sideways. They were in the middle of a large multifamily build—nearly 300 units—and already dealing with material shortages, missed delivery windows, and supplier radio silence. Their original supplier had underquoted, overpromised, and ultimately failed to meet the needs of a growing, multi-phase job.

We stepped in and conducted a full review of their project schedule and upcoming material needs. We consolidated their scattered vendor list, established a delivery rhythm that aligned with their phase releases, and renegotiated pricing on core items through our bulk supply channels.

Not only did we bring the chaos under control—we reduced their material costs by over 14% for the remaining phases. Perhaps more importantly, we restored confidence in their construction process. Site supervisors weren’t chasing deliveries. Subcontractors weren’t idle. And the developer regained control of a budget that had previously been slipping through their fingers.

That success wasn’t about us being clever—it was about taking planning seriously and being willing to invest the time to do it right.

What Most Builders Get Wrong (And How to Get It Right)

Many builders still treat their supplier like an afterthought. They send a takeoff, wait for a quote, and hope for the best. But that approach leaves too much up to chance. It puts your schedule, your margins, and your reputation in the hands of someone who may or may not be fully invested in your success.

At ProPonents, we’re flipping that model on its head. We treat material supply as a critical part of the project lifecycle. We ask better questions, offer real-world solutions, and take ownership of our role in your build. Whether you’re facing rising costs, tight deadlines, or design changes mid-project, we’re not just delivering products—we’re helping you navigate the complexity with confidence.

This kind of partnership doesn’t just protect your budget—it makes you a better builder. It gives your clients more trust in your process, your subs more confidence in their timelines, and your team more bandwidth to focus on the work—not the logistics.

Planning Isn’t a Luxury. It’s the Smartest Investment You Can Make.

If you want to stay on budget in today’s construction environment, you can’t afford to be passive about your materials. You need a plan—and you need a partner who’s willing to help you build it, adjust it, and execute it at every stage of the job.

That’s where we come in.

Let’s sit down before the project gets messy. Let’s look at your drawings, your estimates, your pain points. Let’s talk about where we can tighten the numbers without cutting corners, and where we can plan for contingencies that keep you in control, no matter what curveballs the build throws your way.

Because at the end of the day, it’s not just about saving money—it’s about building predictability into a process that’s often anything but predictable.