Fire Safety in MDUs: Ensuring Resident Safety with Modern Solutions

Fire safety is a top priority for any residential building, but it's especially crucial in Multiple Dwelling Units (MDUs), where the density of residents means that the consequences of a fire can be particularly severe. From prevention to response, MDUs must be designed and maintained with fire safety in mind to protect both residents and property. Advances in technology, new safety regulations, and proactive community initiatives are transforming fire safety protocols in MDUs, making urban living safer for everyone.

In this blog post, we will explore modern fire safety solutions for MDUs, focusing on prevention, early detection, evacuation planning, and community involvement. By taking a comprehensive approach to fire safety, MDUs can ensure that residents are well-protected, minimizing the risk of fire-related incidents and enhancing the sense of security within the community.

Fire Prevention Through Smart Building Design

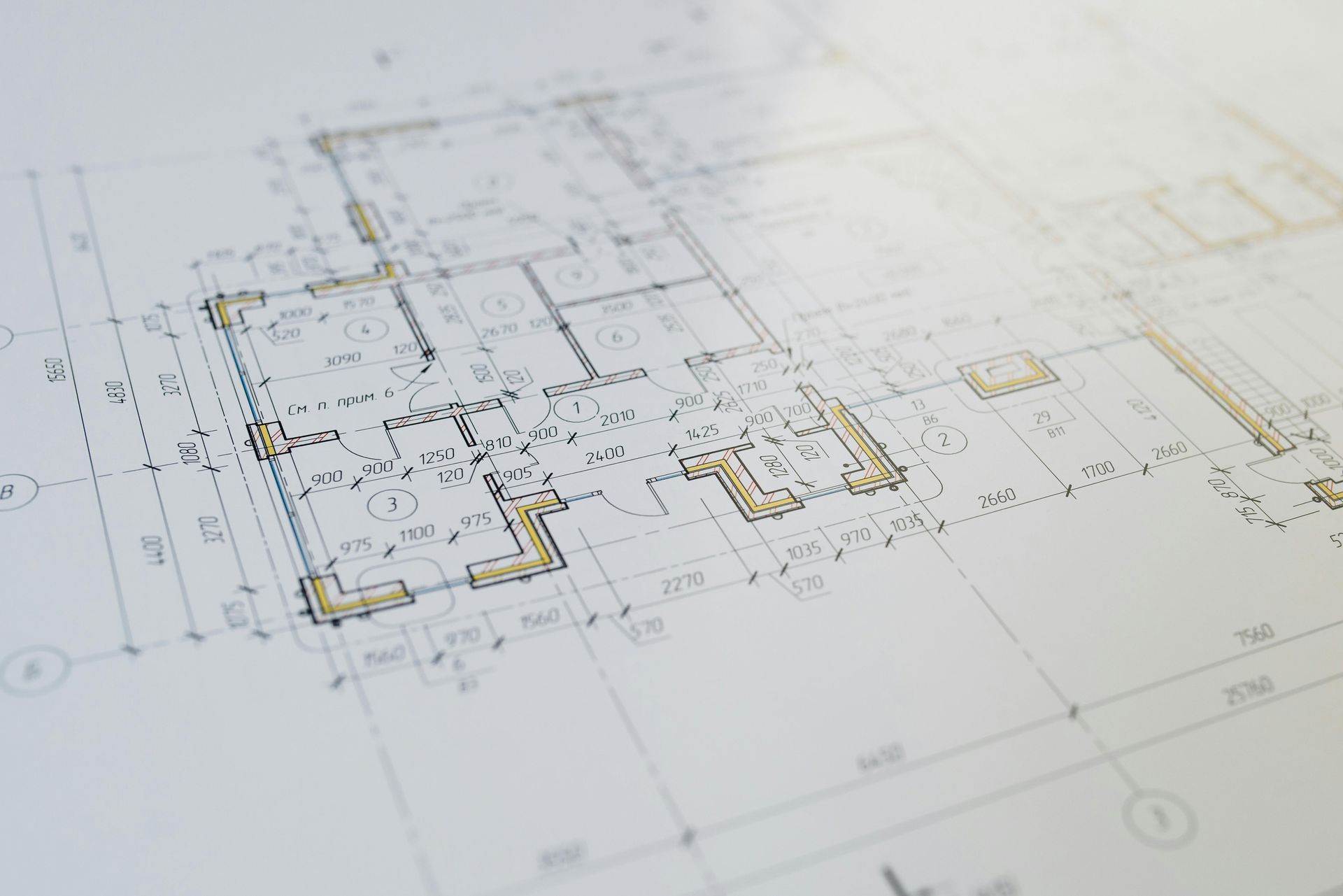

Fire prevention begins at the design phase. Incorporating fire-resistant materials, effective fire barriers, and smart layout considerations can significantly reduce the risk of fire in MDUs. Thoughtful design is the foundation of a safe building that minimizes the potential for fire hazards.

- Fire-Resistant Building Materials: Using fire-resistant materials such as concrete, steel, and fire-rated drywall is one of the most effective ways to prevent fire from spreading within an MDU. These materials are specifically designed to withstand high temperatures, providing crucial time for residents to evacuate in the event of a fire.

- Compartmentalization: Compartmentalization is a key strategy in fire prevention. By dividing a building into fire-resistant compartments, developers can help contain a fire to a small area, limiting its spread and giving residents more time to evacuate. Fire-rated doors and walls are essential components of compartmentalization and play a critical role in protecting residents during a fire emergency.

- Electrical Safety: Electrical issues are a common cause of residential fires, and ensuring electrical safety is crucial in MDUs. Installing modern, code-compliant electrical systems and conducting regular inspections can help identify and address potential fire hazards. In addition, using fire-resistant electrical cabling and circuit breakers that automatically shut off when they detect an overload can further reduce the risk of electrical fires.

Advanced Fire Detection and Alarm Systems

Early detection is critical for minimizing the impact of a fire. Advanced fire detection and alarm systems provide residents and emergency responders with the crucial information they need to act quickly and safely. Modern fire detection technologies are designed to be more accurate and responsive, reducing the likelihood of false alarms and improving overall safety.

- Smart Smoke Detectors: Smart smoke detectors are a significant upgrade from traditional detectors. These devices are capable of detecting both smoke and carbon monoxide, providing residents with comprehensive protection. Smart detectors can also be connected to residents' smartphones, sending alerts in real-time and allowing for faster response even when residents are not at home.

- Centralized Fire Alarm Systems: In MDUs, centralized fire alarm systems are essential for ensuring that all residents are alerted in the event of a fire. These systems can be connected to a central monitoring station that notifies emergency services as soon as an alarm is triggered, ensuring a prompt response. Centralized systems can also include visual and auditory alarms to accommodate residents with hearing impairments.

- Heat Sensors: Heat sensors are another important component of fire detection systems. Unlike smoke detectors, which detect particles in the air, heat sensors detect rapid changes in temperature. Heat sensors are particularly useful in areas like kitchens, where smoke detectors may be prone to false alarms. By incorporating both smoke and heat detection technologies, MDUs can provide comprehensive fire detection coverage.

Sprinkler Systems and Fire Suppression

Sprinkler systems and fire suppression technologies are crucial for containing and extinguishing fires before they have a chance to spread. By installing effective fire suppression systems, MDUs can significantly reduce the risk of widespread damage and ensure resident safety.

- Automatic Sprinkler Systems: Automatic sprinkler systems are one of the most effective tools for controlling and extinguishing fires. These systems activate when they detect heat, releasing water to suppress the fire and prevent it from spreading. In MDUs, sprinkler systems can be installed throughout the building, including in individual units and common areas, providing comprehensive protection.

- Dry Chemical Suppression Systems: In certain areas where water damage may be a concern, such as electrical rooms or server rooms, dry chemical suppression systems can be used. These systems release a chemical agent that quickly suppresses the fire without causing water damage to sensitive equipment.

- Fire Extinguishers: Fire extinguishers are an important tool for residents to use in the event of a small fire. MDUs should provide easily accessible fire extinguishers throughout the building, along with clear instructions on how to use them. Regular maintenance checks should be conducted to ensure that all fire extinguishers are in good working order.

Evacuation Planning and Resident Safety Education

A well-thought-out evacuation plan is essential for ensuring that residents can safely exit the building in the event of a fire. Evacuation planning should be complemented by ongoing resident education to ensure that everyone is familiar with fire safety protocols and knows what to do in an emergency.

- Clearly Marked Exits: All exits should be clearly marked with illuminated signs that are visible even in low-light conditions. Stairwells should be accessible, well-lit, and free of obstacles to ensure that residents can quickly and safely evacuate. Emergency lighting should be installed to guide residents in case of power outages.

- Regular Fire Drills: Conducting regular fire drills is an important part of evacuation planning. Fire drills give residents the opportunity to practice evacuating the building and familiarize themselves with emergency exits. MDUs should conduct fire drills at least once a year to ensure that all residents are prepared in case of an emergency.

- Resident Fire Safety Education: Educating residents about fire safety is crucial for minimizing risks and ensuring that everyone knows what to do in the event of a fire. MDUs can host workshops or distribute educational materials that cover topics such as fire prevention, how to use a fire extinguisher, and what to do when the fire alarm sounds. By empowering residents with knowledge, MDUs can create a safer living environment for everyone.

Community Involvement and Fire Safety Culture

Building a culture of fire safety within an MDU community is essential for ensuring that everyone plays a role in keeping the building safe. Community involvement in fire safety initiatives can help reinforce best practices and foster a sense of collective responsibility.

- Fire Safety Committees: Establishing a fire safety committee composed of residents and building management can help ensure that fire safety remains a priority. The committee can be responsible for organizing fire drills, conducting safety inspections, and addressing resident concerns about fire hazards. Having a dedicated group focused on fire safety helps maintain a proactive approach to identifying and mitigating risks.

- Communication Channels: Effective communication is key to maintaining fire safety in an MDU. Building management should establish clear communication channels to inform residents of fire safety updates, upcoming drills, and any maintenance work that may affect fire safety systems. Digital communication tools, such as email newsletters or community apps, can be used to keep residents informed and engaged.

- Reporting Hazards: Encouraging residents to report potential fire hazards is an important aspect of community involvement. Whether it's identifying blocked fire exits, faulty wiring, or improper storage of flammable materials, residents should feel comfortable reporting hazards to building management. Creating a culture where fire safety concerns are taken seriously helps ensure that risks are addressed promptly.

Prioritizing Fire Safety in MDUs

Fire safety in MDUs is a multifaceted challenge that requires a combination of smart design, advanced technology, effective planning, and community involvement. By incorporating fire-resistant materials, advanced detection systems, reliable suppression technologies, and comprehensive evacuation plans, MDUs can significantly reduce the risk of fire-related incidents and ensure the safety of all residents.

Creating a culture of fire safety within the community is also crucial for maintaining a safe living environment. Through resident education, regular drills, and proactive communication, MDUs can empower residents to play an active role in fire prevention and response. When everyone works together to prioritize fire safety, MDUs can offer a secure and comfortable living experience for all.

As urban living continues to evolve, the emphasis on fire safety in MDUs will only grow stronger. By staying ahead of technological advancements, adhering to safety regulations, and fostering a culture of safety, developers and building managers can create environments where residents feel confident that their well-being is always a top priority. Fire safety is not just about meeting regulatory requirements—it's about creating a home where residents feel safe, secure, and protected from harm.