How Builders Navigate Lead Times and Inventory Fluctuations in a Volatile Market

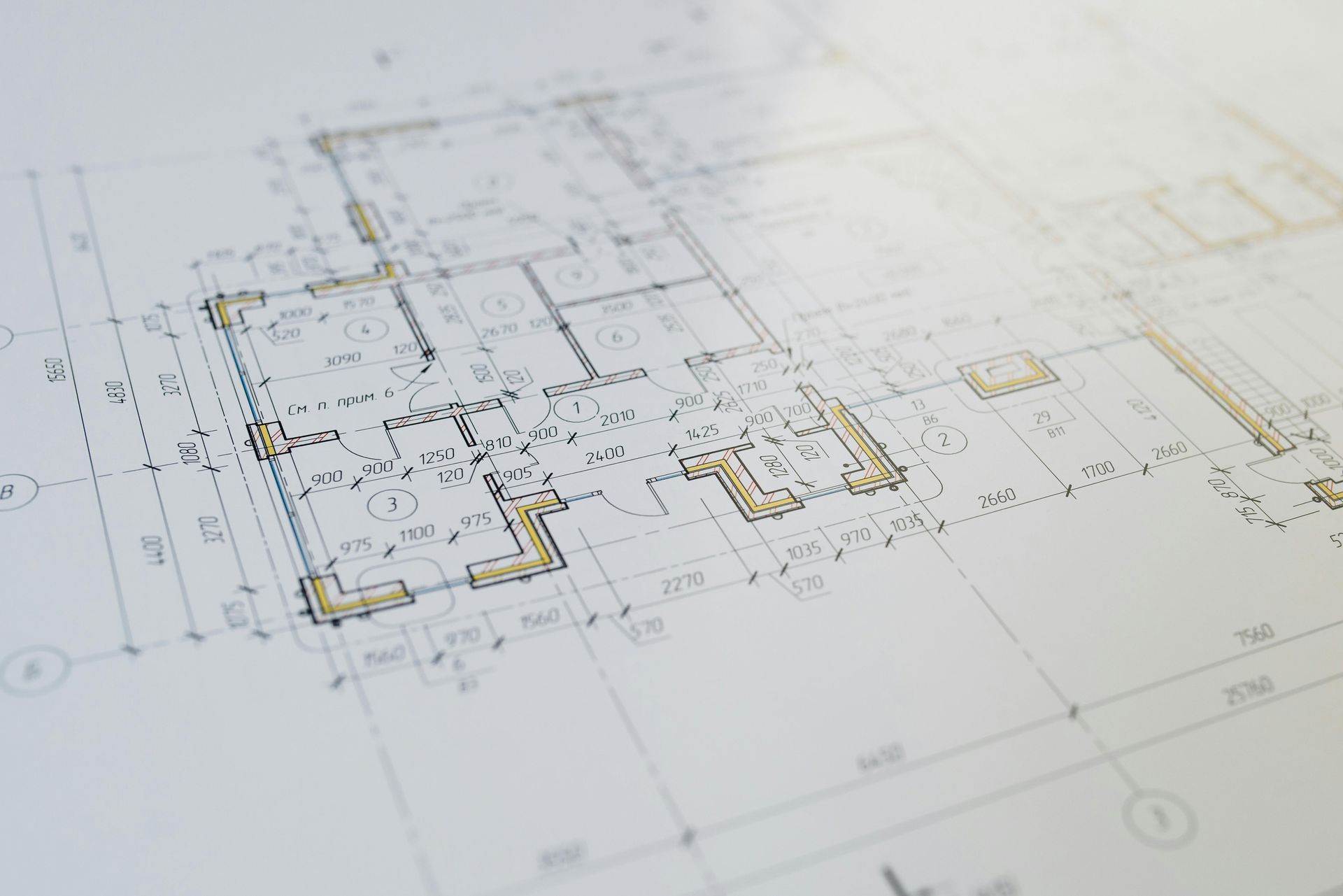

The blueprint might be precise. The schedule might be tight. The team might be ready. But if the materials don’t show up when they’re supposed to, nothing else matters.

That’s the quiet reality every builder, developer, and project manager faces in today’s construction world. Lead times shift without notice. Inventory surges and slumps. And the supply chain—once predictable—is now a moving target that can change week to week.

Over the past few years, the industry has experienced what can only be described as supply chain whiplash. Products that were once always in stock suddenly disappear. Delivery timelines stretch from days to months. Price volatility can swing margins in either direction. And for builders who still operate on old-school ordering models—waiting until they need something to place the order—the impact is harsh, costly, and often irreversible.

At ProPonents, we’ve built our entire supply strategy around one question: how can we help our clients stay ahead of the curve? How can we make sure they’re not reacting to supply chain issues, but anticipating them—and building plans that keep projects moving no matter what the market throws at them?

The answer, we’ve learned, lies in a mix of early communication, strategic sourcing, and total transparency.

Let’s unpack what that looks like in practice—and why it matters more now than ever.

The New Normal: Uncertainty as a Constant

The idea of “just-in-time” material supply used to be a point of pride. You could place an order with a day or two of lead time, expect a delivery window, and schedule your crews accordingly. It was efficient. It worked—until it didn’t.

Then came a global pandemic. Labor shortages. Factory shutdowns. Container backlogs. Raw material scarcities. And even as things slowly stabilized in some areas, the new reality is clear: supply chain risk is now a permanent part of the construction equation.

That risk doesn’t just affect exotic or specialty products. It affects everything—from lumber and adhesives to fasteners, roofing, siding, insulation, doors, windows, and plumbing rough-ins. And it doesn’t just hit once per project—it comes in waves, changing based on season, location, and broader market pressures.

What this means is that builders can no longer afford to wait until the last minute or assume availability. Because even if the price is right, the wait time may not be. And in construction, time is money.

Planning Forward, Not Backward

The most successful projects we support today don’t just have material quotes—they have material roadmaps.

That starts with getting involved earlier. Before the concrete is poured. Before the plans are finalized. Sometimes even before the permits are pulled. It’s in those early weeks that we can do the most good—reviewing schedules, identifying high-risk items, and building a procurement strategy that actually reflects the build, not just a bill of materials.

We work closely with developers and GCs to assess lead times on a rolling basis. Not just what the spec sheet says, but what our suppliers are actually reporting in real time. We identify products that might be flagged for future shortages. We explore comparable options that are in stock now, not “maybe next quarter.” We lock in priority allocations for long-lead items and build phased delivery timelines so that crews aren’t waiting on site—or storing pallets of product they won’t use for weeks.

The entire strategy shifts from reactive to proactive. And once that shift happens, everything downstream starts to run smoother.

The Hidden Cost of Playing Catch-Up

It’s easy to think of inventory issues as a materials problem. But the ripple effects go much deeper. When lead times aren’t accounted for, the consequences cascade across the entire job.

Crews are delayed. Subcontractors are rescheduled. Trade conflicts arise as timelines shift. Change orders multiply. And suddenly, a missed delivery of window trim or plumbing fittings becomes the reason why a floor sits empty or an inspector can’t sign off.

Worse still, rushed orders often lead to paying more for expedited shipping, settling for subpar alternatives, or being forced into redesigns that disrupt budgets and confuse crews. We’ve seen projects bleed tens of thousands of dollars simply because the procurement plan wasn’t built to anticipate these kinds of disruptions.

At ProPonents, we don’t believe builders should have to bear that burden alone. That’s our job—to keep you ahead of the curve so the jobsite can stay ahead of schedule.

Total Visibility: The Cure for Uncertainty

One of the most valuable tools we offer isn’t a product. It’s clarity.

We keep our clients informed—not just about what’s happening now, but what’s coming. We communicate lead time shifts before they hit. We notify you when a supplier flags an upcoming shortage. We track every delivery window, every shipping update, and every inventory movement so that your team knows what to expect—and when to expect it.

We believe transparency builds trust. And when you know what’s happening behind the scenes, you can make better decisions in the field. You can communicate more confidently with stakeholders. And you can plan with purpose, not panic.

That’s what separates a vendor from a partner. And that’s what we strive to be.

Real Results in the Field

Not long ago, we supported a multi-building townhome project with a tight delivery schedule and limited staging capacity. The builder had previously struggled with other suppliers, who couldn’t coordinate drop-offs or offer real-time updates. That meant crews were often idle, or working around missing items, or overwhelmed by too much material dropped off at the wrong time.

We stepped in and built a site-specific delivery schedule based on their framing and finishing rhythm. We locked in long-lead items early, gave weekly availability reports, and maintained rolling forecasts for every SKU on the job. Not only did the project stay on time—it finished two weeks ahead of schedule, with zero material-related change orders.

That’s not luck. That’s logistics, strategy, and partnership working in sync.